13929258449

13929258449

13929258449

13929258449

The products produced by 3D printing of titanium alloy powder have the advantages of high hardness, low thermal expansion coefficient, and good corrosion resistance.

Comparison of Three Main Preparation Methods for Titanium Alloy Powder

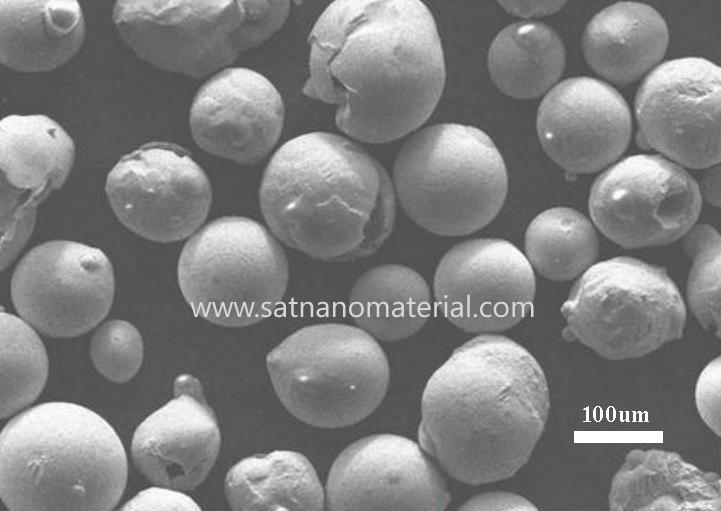

1.1 Plasma Rotating Electrode Method This preparation method uses electrodes made of metal or alloy, and the end face is heated by an arc to melt into a liquid. Under the action of its own high-speed centrifugal force, the liquid is thrown out and crushed into small droplets, and then condensed into powder. This process can adjust the electrode speed to control the powder particle size and is one of the ideal ways to obtain spherical powder. It has the characteristics of high sphericity, good powder flowability, high loading density, and smooth surface. The printing process control is reliable, and it is not easy to produce defects such as precipitated gases and cracks. However, due to the limitation of centrifugal speed, the titanium alloy powder produced has a coarser particle size and a relatively concentrated particle size distribution range, resulting in higher costs and lower productivity.

1.2 Plasma wire atomization method This preparation method uses different alloy wires as raw materials and processes them into spherical powders. It was first independently developed by a Canadian company and has independently manufactured equipment, which has a certain influence in the industry. The spherical powder produced by this technology has the advantages of high powder yield, low impurities, and high work efficiency, making it suitable for the development of titanium alloy powder. However, there are also trace amounts of "satellite balls" and very little adhesion phenomenon, which have little effect on the performance of use.1.3 Gas Atomization Method Gas atomization method is a method that uses high-speed airflow to crush metal liquid flow, rapidly solidify and form powder. This method only needs to overcome the intermolecular forces between liquid metal atoms to disperse it. Basically, any material that can form a liquid can be atomized. Currently, vacuum atomization method and inert gas atomization method are widely used. The titanium alloy powder prepared by gas atomization method has the characteristics of rapid solidification, no hollow particles, and good sphericity, but the powder yield is low and the production cost is high. At present, most of the atomization technology used in China to produce titanium and titanium alloy powders has a low powder yield.

Several preparation methods have their own advantages and disadvantages. After analysis and comparison, the plasma rotating electrode method was selected for atomization preparation of titanium alloy powder, and the effect was significant.

SAT NANO is a best supplier of titanium alloy powder and TC4 Ti6Al4V alloy powder in China, we can offer 0-25um, 15-45um, 15-53um, 45-75um, 45-105um particle, if you have any enquiry, please feel free to contact with us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com led_zhiding

led_zhiding + 8613929258449

+ 8613929258449