13929258449

13929258449

13929258449

13929258449

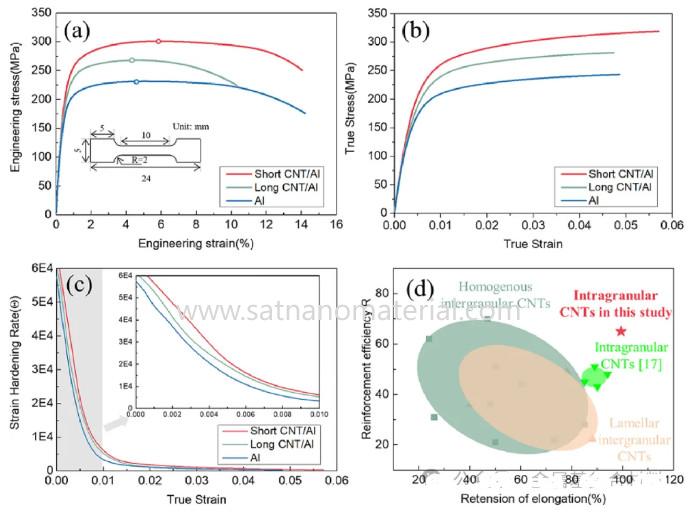

Carbon nanotubes (CNTs) reinforced aluminum composites with unique intragranular dispersion were obtained using ultra short carbon nanotubes, and nanoscale carbon nanotubes were uniformly distributed within ultrafine aluminum grains. Compared with typical CNT/Al composite materials with intergranular carbon nanotube dispersion, this intragranular carbon nanotube/aluminum composite material has stronger dislocation pinning and retention ability, thereby exhibiting both strength and ductility improvement. The current intragranular dispersion strategy will provide ideas for the preparation of strong and tough nanocarbon reinforced metal matrix composites.

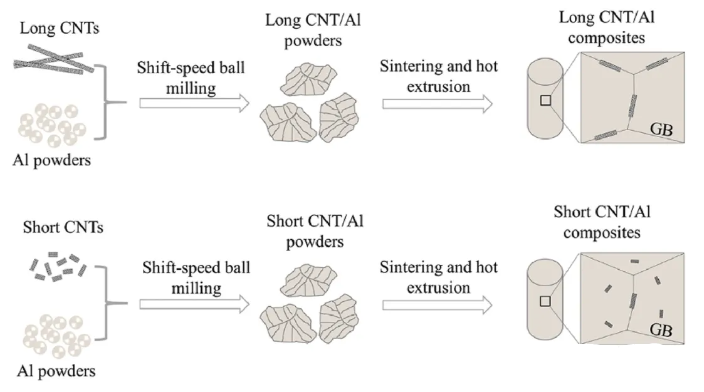

Figure 1. Schematic diagram of preparing long and short CNT/Al composite materials through variable speed ball milling, sintering, and hot extrusion processes

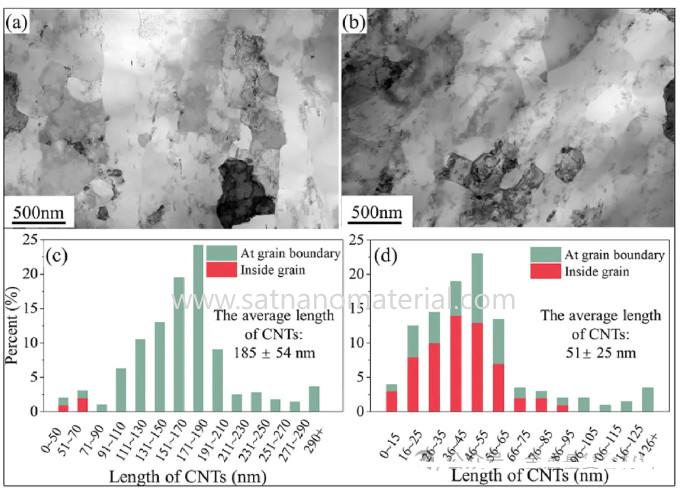

Figure 2. TEM images of long (a) and short (b) CNT/Al composite materials. The percentage and length distribution of intergranular and intragranular carbon nanotubes in extruded composite materials: (a) long CNT/Al composite materials, (b) short CNT/Al composite materials.

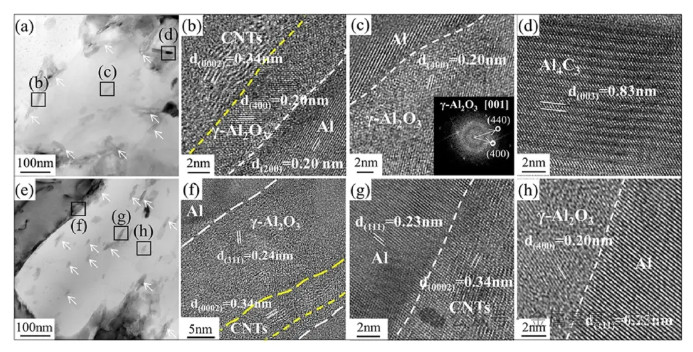

Figure 3. (a) STEM image of long carbon nanotube/aluminum composite material, with white arrows displaying carbon nanotubes and (b-d) HRTM displaying carbon nanotube structure, with γ - Al2O3 and Al4C3; (e) Short CNT/Al composite material, white arrow represents CNTs, (f-h) HRTEM represents the structure of CNTs and γ - Al2O3.

Figure 4. (a) Engineering tensile stress-strain curve, (b) True stress-strain curve, (c) Strain hardening rate curve of Al and long short CNT/Al composite materials. (d) Elongation rate and strengthening efficiency.

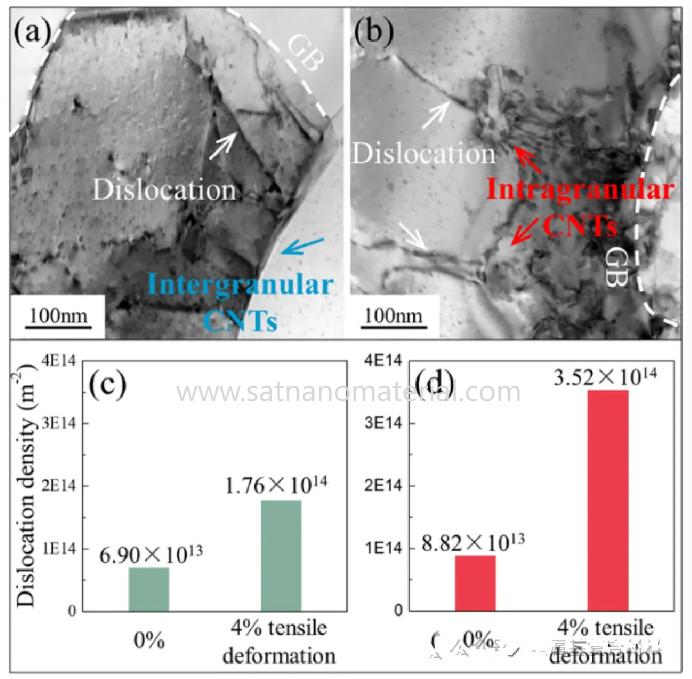

Figure 5. STEM images and dislocation density of composite materials after 4% tensile deformation: (a), (c) long CNT/Al composite materials, and (b), (d) short CNT/Al composite materials.

SAT NANO is one of the best supplier of carbon nanotube, we can offer MWCNT, MWCNT-OH, MWCNT-COOH powder, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com led_zhiding

led_zhiding + 8613929258449

+ 8613929258449